Then you need control electronics to be reliable and safe. Many times, the system must also be certified for safety, especially if, in the event of a malfunction, personal injury could occur.

Project vision development

When developing a system, it is important to first clarify

who will work with it (install, maintain and repair it), who will use it and who will sell it.

These are sometimes called ‘steak holders’.

The vision describes for each of these parties, what expectations they have, and what they consider important.

Why? Ultimately, these expectations translate is requirements for the final system.

Example: Developing a new boiler.

- Installers want it to be compact, easy to connect and, above all, compatible with existing systems.

- The end user wants it to be safe, favorably priced, and not to have to worry about it. That rules out periodic maintenance, or it must be scheduled ‘automatically’.

- Sales want a clear simple device, where everyone easily understands the benefits. But there must also be unique advantages over competing systems. In addition, his margin must be sufficient.

If there are contradictions, they must be resolved at this level. Especially not later (e.g. when the prototype is ready!).

Project Realization

In the realization step, the product vision is translated into technical requirements. But always in such a way that it is optimized to the product vision. The product vision enables the technical developers to come up with the best proposals, without wasting time on proposals that are not suitable within the vision. This keeps the cost of the electronics development) in control.

The technical requirements are then used to build the product.

Boiler example.

The controller provides:

- Normal operation (heating and hot tap water).

- Statistics data on wear of parts (hours and switching on)

- Reports statistics data via the Internet to the management system

- The electrician links an installation to the location

Device Certification

All devices must have the CE mark. Depending on the type of device, this will require a safety approval.

If a boiler malfunctions, and e.g. does not stop heating, a fire may occur, resulting in personal injury.

Therefore, the

control electronics of the appliance must be made so that a second independent circuit intervenes and ensures that overheating is not possible.

The device is then certified via an expert verification.

Programming and your influence

Theoretically, you can leave programming entirely to the

electronics development) team.

Still, there comes a point later (usually earlier) when you want to be able to experiment with new ideas to improve the device in order to maintain your competitive positions.

Then it is very practical when you can easily make these adjustments in-house. That saves a lot of communication time, and you keep the

knowledge within the company.

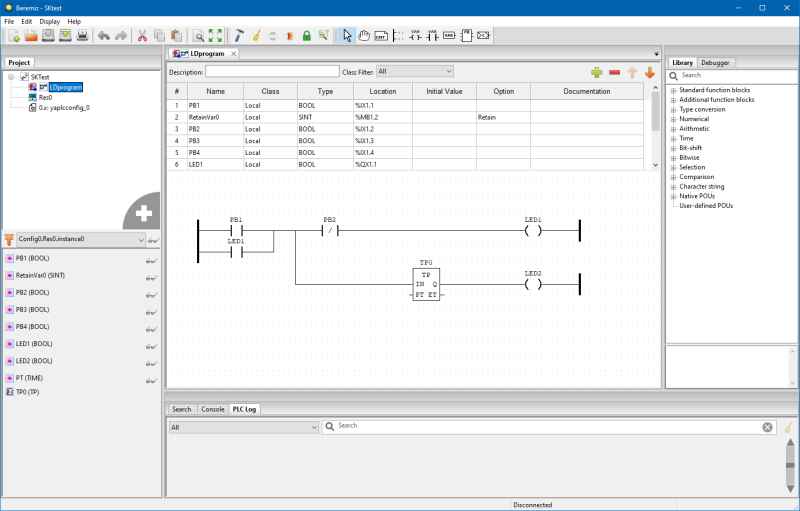

Conveniently, PLC programming is taught on many engineering courses, making PLC programmers more readily available than C/C++ programmers. The IEC 61131-3 standard also ensures that everyone speaks the same language….

Investment

It does require a one-time investment (for the electronics development), to provide the right electronics, and optimize for cost. That investment is then amortized over several years of production.

The final product price depends on a number of factors and must be considered on a case-by-case basis. The most important factors, of course, are the quantity and batch size.

In a short phone call, you may find out a lot.

A project then comprises the steps:

- Requirements

- Analysis

- Overall design

- Electronics implementation

- Electronics qualification

- Customer acceptance

- Testing

- Production preparation

- Production